WJT 2005 Cologne - Wolke Marienfeld

General information

-

Home page

www.form-TL.de

-

Location address

Marienfeld

-

Location country

Germany

-

Year of construction

2005

-

Name of the client/building owner

Weltjugendtag GmbH, Cologne

-

Function of building

Religion

-

Climatic zone

Temperate - cold winters and mild summers

-

Type of application of the membrane

covering

Description

The world youth day takes place between the 15th and the 21st of August 2005. It is a pilgrimage of young people from all over the world to the area around Cologne, with common prayers and activities in Cologne, Düsseldorf and Bonn. After a welcome celebration with the Pope and an International Festival in Cologne City, they arrive finally at the Marienfeld, where the Vigil and the concluding Mass takes place form the 20th to the 21st of August.

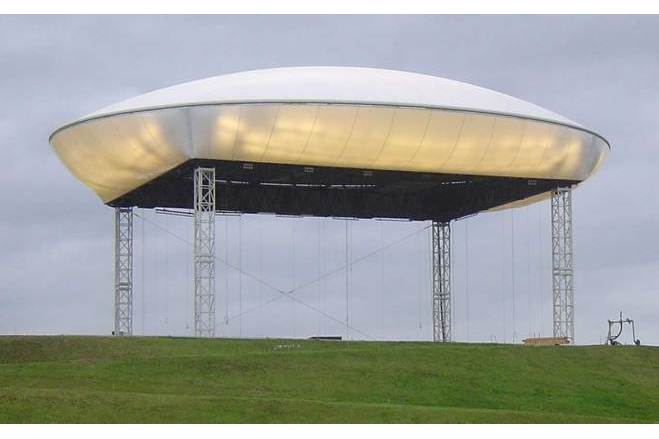

For the Vigil and for the concluding Mass, more than 800.000 pilgrims are expected, and therefore an area of approximately 2 km width and 1.5 km length has been build up, including a 10 m high hill, where on top the so called Cloud is located, a pneumatic structure as stage roof for the Pope.

The Cloud is realised based on a modular truss system, that is used for Rock ?n Roll stages, and can be adapted easily for the requirements of individual events. The structure is for temporary use, and will be dismantled after the 22nd of August.

On a rigid base structure, 4 columns (towers) are installed. The grid for the roof is built by 1.8 m high main trusses and a second layer of 1.3 m secondary trusses. In the corner of the grid special Corner blocks are installed, which allow to lift the roof-grid from the ground with electric winches. These winches are part of the standard stage system. To form the Cloud, the perimeter of this standard system is extended by an elliptical ring, where the upper cushion is connected, and where the top of the lateral cushions is connected. At the lower chord of the main truss a steel profile is attached, for the clamping of the membrane

The pneumatic structure has in the final design been divided in 5 individual cushions. One large cushion lying on top of the grid, and spanning 39 by 32 m, and four smaller cushions, which form the border area with a length of 22 or 27 m, and a width of 6 or 6.5. At the borderline the cushions are connected with extruded clamping profiles. The total volume of all cushions is approximately 2500 m³, and the inner pressure is 300 Pa.

The concept of the Cloud required an illumination to get a glowing cloud by night or in the dawn. Therefore inside of the cushions fluorescent tubes are installed. In the upper cushion are 184 LHGL-lamps with 4 tubes each, and in the side cushions are 260 LHGL-lamps in total. This gives approximately 1800 fluorescent tubes (warm white) to illuminate the cloud. Each of them can be dimmed individual.

The membrane on the outer skin is a PVC coated polyester type II with a translucency of 22%, which was also a requirement for the illumination of the cloud. Due to this high translucency the g-value went up to 30%, and it had to be take into account the heating up of the cushions under solar radiation, and with the heat sources inside the cushions. A numerical simulation, based on the warmest summer day, with maximum radiation and with no wind has shown for the initial design a temperature of 100°C in the top cushion and more than 60° in the border cushions. After a test under 80°C it was clear that the membrane has

the full stability up to 80°C and for the lamps inside the cushion a maximum of 80°C could be accepted when they are off, but under service the temperature had to be a maximum of around 40°C.

To avoid the high temperature a gap of 50 mm between the ring beam and the lower clamping line has been introduced, do ventilate the inner space. In the upper cushion two overflow valves have been introduced to allow an air exchange up to 4 times per hour, what was possible with the presumed 2 fans. Each of them has a capacity of 5000 m³/h. To minimize the noise in the normal situation only 1 fan is working with 50%, and under high temperature the second fan is started also with 50%, and if the temperture is still increasing then both are set to 100%.

With these modifications the numerical simulations have been adapted and the temperature in all cushions and in the air space have been analysed over the day. With this measure a maximum temperature around 70°C could be achieved in the top cushion at 2 p.m., and around 40°C between 7 and 8 p.m. what was acceptable to start the illumination at the dawn.

Due to the chosen system of modular trusses the installation was very quick, and most parts have been installed at the ground level, before lifting up the Steel Grid. The Installation took 10 days, including the additional work for the light installation. For the dismantling of this temporary structure a 2 day period is estimated. The complete structure can be reused then for another event.

Description of the environmental conditions

Material of the cover

-

Type (code)

II

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

960

-

Maximum height (m)

12.2

-

Total length (m)

39

-

Total width (m)

32

Duration of use

-

Temporary or permanent structure

Temporary

Involved companies

Editor

-

Editor

Bernd Stimpfle