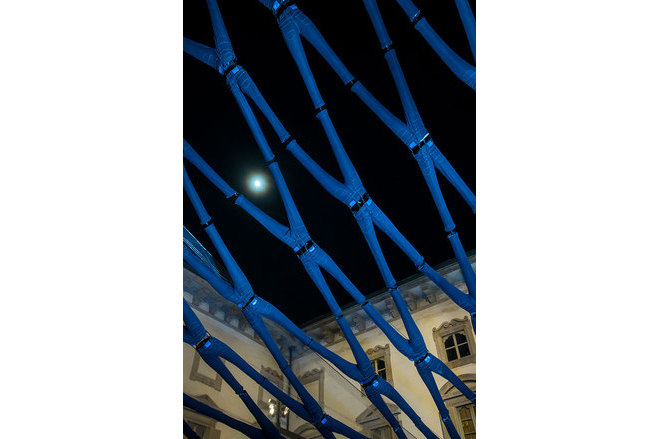

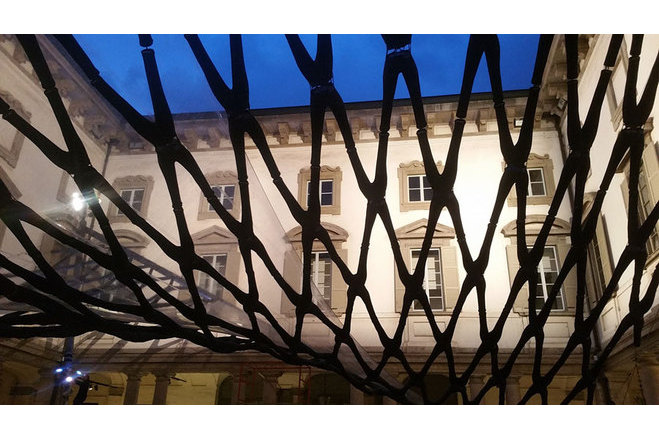

“Off the Cuff” installation at Palazzo Litta

General information

-

Location address

Palazzo Litta, Corso Magenta, 24, Milan

-

Location country

Italy

-

Year of construction

2017

-

Name of the client/building owner

Mosca Partners

- Function of building

-

Type of application of the membrane

internal

Description

The pavilion was designed by Diller Scofidio + Renfro, an interdisciplinary design studio based in New York City that integrates architecture, visual arts, and performing arts. According to Liz Diller, the initial concept was based on the idea of “using ready-made modules – actually misusing them – for architectural purposes. In the back of our minds – and this might sound very peculiar – we have always wanted to use actual trousers as a module”.

Maco Technology and the University of Nottingham were contacted in January 2017 in order to provide the support for the final engineering, manufacturing and installation of the pavilion by the 3rd of April 2017. The project has been challenging under several aspects such as the extremely tight time schedule, the constraints imposed by the Monuments and Fine Arts Department, the building materials used and the complex 3D modelling of the structure.

The elongation of the denim under load and in presence of different levels of humidity has been addressed through adjustable connections (cable ties) in correspondence of the cuffs and the waist of each unit and adding a set of adjustable Kevlar ropes between the steel frame and the mesh in order to introduce the required level of pretension into the tensile structure. The length of the Kevlar rope was controlled by means of a GI-GI plate, a multiuse belay plate commonly used for climbing. The mesh was supported by a rigid steel structure designed to avoid the transfer of additional loads to the existing building apart from the gravity loads. The final structural solutions did not require permanent foundations, anchoring points or heavy ballasts. The vertical loads have been distributed on the ground through thick timber boards. In order to facilitate the installation of the steel structure, the two main posts have been designed with pinned joints able to allow the rotation from the initial horizontal plane, used for the connection of the components at ground level, to the vertical plane required by the final geometry of the pavilion. Each post was stabilized by two cables (Full Locked Coil by Redaelli Tecna) connected to the basement.

Description of the environmental conditions

Material of the cover

Main dimensions and form

-

Covered surface (m2)

400

Duration of use

-

Temporary or permanent structure

Temporary

Involved companies

-

Architects

Diller Scofidio + Renfro

-

Engineers

Thornton Tomasetti

-

Contractors

Maco Technology srl

Editor

-

Editor

Evi Corne