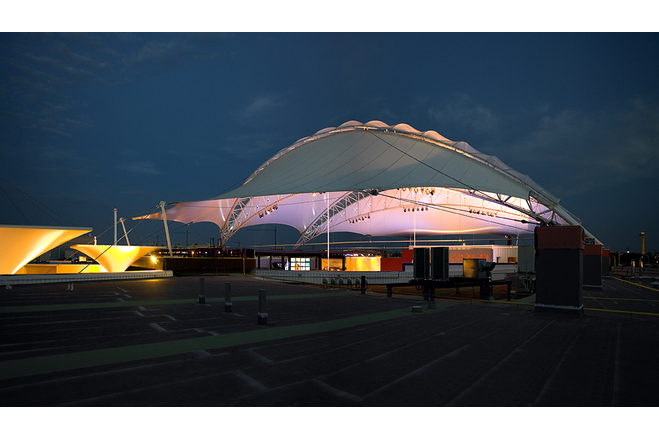

Imaginalia Shopping Centre Roof

General information

-

Location address

Albacete

-

Location country

Spain

-

Name of the client/building owner

PROCOM

-

Function of building

Shops and stores

-

Degree of enclosure

Hybrid structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

- Sun protection

- Wind protection

Description

At the end of spring 2005, the project management company Bovis Lend Lease got in contact with IASO S.A. to work together on a project designed by L-35 Architects. The project was for the biggest commercial centre of the Castilla La Mancha region in Spain. The centre is located in the city of Albacete, and is called “Imaginalia.”

The “textile part” of the project involved a 2120m2 roof over the central square, which looks like an amphitheatre amidst more than 45.000m2 of commercial space. One of the most important issues, apart from obvious functional and quality aspects, was the timing: all work had to be finished before the end of November 2005.

Immediately the definition of the geometric parameters was started, in order to be able to calculate the necessary concrete anchors and supports. After defining the geometry, both membrane and steel structure was modelled on computer, and then calculated. All partial results could now be coordinated and integrated in the entire project.

In order to reach the deadline, all different and individual aspects of the entire project had to be studied and executed almost simultaneously, including security programs for installation and signed projects.

This pointed out that the two 60m long steel arches posed a problem, for two important reasons. First of all, there was the issue of transportation; and secondly, movements at the fixing points had to be avoided, to prevent enormous moments in the concrete pillars, which were not taken in account in the initial project.

Those problems were solved, of course: the arches were divided into three parts for transportation, and eventually welded together on site. And to avoid the transmission of the arches movement to the concrete pillars, linear bearings were placed at the end joints.

Next step was putting everything together. The steel structure was designed and fabricated; the membrane patterning was defined and then manufactured; cable sections were calculated, … Then the manufacturing and installation schedule and plans were proposed, including the necessary on site preparation.

The last part of the design consisted of the ETFE single layer cover on the central parts of each arch. An ETFE-film was chosen as a substitute for glass for reasons of low weight and transparency. To avoid high stresses in the complicated single ETFE layer system, an independent secondary steel structure was placed on top of the steel arches. External tensioning devices provided the necessary biaxial stress for the ETFE-film.

As an extra feature to the Imaginalia Shopping Centre, the entrance of the movie theatre was to be emphasized by three inverted cone shaped canopies. This particular detail was the very final part of the project.

On the 22 of November at about noon the last part of the ETFE roof was tensioned and at night the opening of the commercial centre could be celebrated. In the end, the complete production process, from design and engineering to manufacturing and installation, was fulfilled in an extremely short period of time, but with the feeling of a satisfying final result.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

Ferrari 1302 Fluotop T2

Main dimensions and form

-

Covered surface (m2)

2120

Duration of use

-

Temporary or permanent structure

Permanent

-

Convertible or mobile

Convertible

Involved companies

-

Architects

L35 arquitectos

-

Engineers

IASO, S.A.

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Evi Corne