Dubai Creek Marina Club

General information

-

Location address

Dubai

- Location country

-

Name of the client/building owner

HH Sheikh Mohammed bin Rashid al Maktoum

-

Function of building

Sport

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Arid - dry and hot all year

-

Number of layers

mono-layer

Description

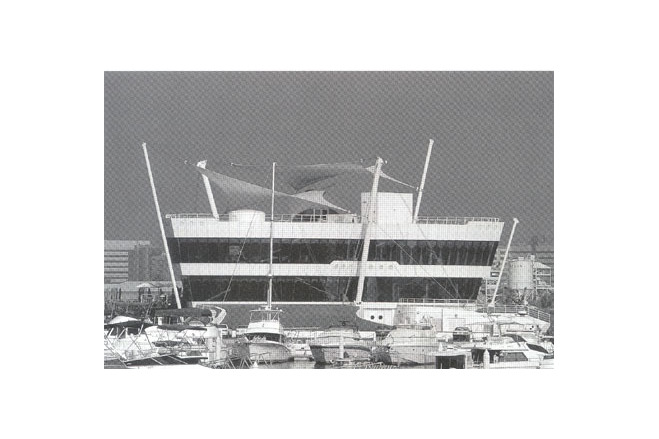

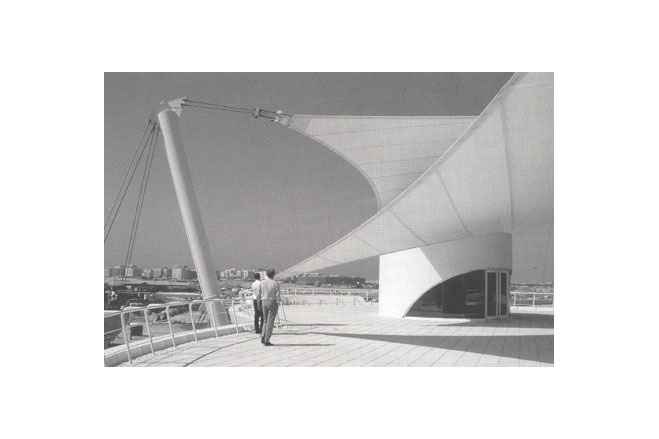

The Yacht Club is part of a larger building complex, which contains both a golf club and a golf academy and a chandlery with a boat workshop. It lies directly on the waterfront above the Dubai Creek, which here is already tidal. The contract for the planning of the golf club was awarded as the result of an international architectural competition, while the design for the Yacht Club was developed in direct contact and cooperation with the client. Although originally to be designed like the golf club, the client later decided to aim for a completely different, modern architectural concept, which ultimately led to the existing design.

Design

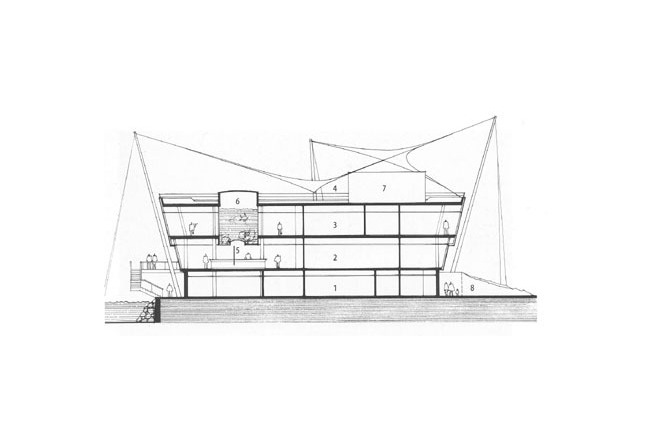

Since the golf club symbolically represents an Arab dhow, the traditional two-masted boat of the Gulf region, the architect concluded that in analogy the Yacht Club should resemble a modern ship. The building is composed of three parts, each shaped like a ship's prow; the parts are of unequal size and have a common internal service core. A continuous glass facade along the entire building is made possible by the clover-leaf plan of the building. The facade is curved following the building's perimeter and leans out at 15° to the vertical, so that the ship-shaped character of the building is reinforced. The roof terrace is covered by two overlapping sails made from coated fabric which provide shade to the area below. They are carried by six outside masts made from steel tube, which are completely separated from the building. The tube masts are also inclined outwards, at the same angle as the glass facade, and are guyed toward the outside by steel wire ropes and anchored in concrete foundations, some of which are under water. Each floor has a 'promenade deck?, whereby the marine theme is continued in the interior. The design of the steel cable structure and its anchorages posed particular problems, since the guy ropes, which become very hot in the summer heat, should be arranged in such a way that nobody can touch them nor run into them by mistake; they should, nevertheless, run close by the building so that they could be read as part of the structure and the marine theme. From the desired position of the building directly above the water resulted the necessity of an effective corrosion protection in this hot and humid marine environment. On the waterfront, directly in front of the building and above the water, extending over the entire length of the building, there is a seating deck made in wood planking, supported on piles in the Dubai Creek.

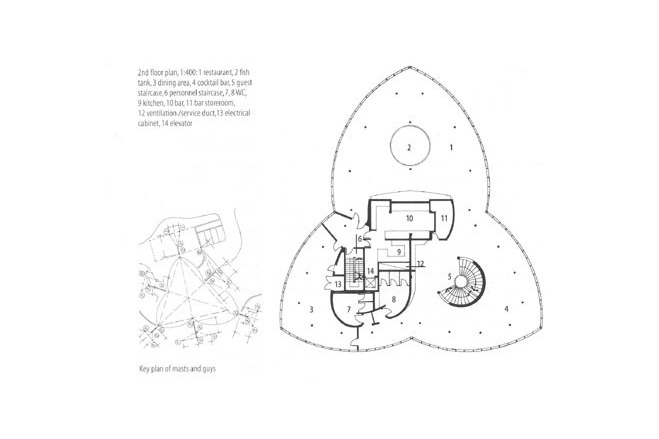

Plan, functions

The upper level of the building houses a restaurant with bar and a large acrylic fishtank, 5.0 m in diameter. The entrance floor contains administration rooms and a bar, with a view up into the fish tank directly above through its dome-shaped acrylic floor. The basement contains service rooms, kitchens, staff rooms and locker rooms for the club members.

Description of the environmental conditions

Construction

The building was erected using the fast track method, as were the other buildings of this complex. The design was approved and released for execution in November 1991; 14 months later, in January 1993, the Yacht Club was opened.

Structure

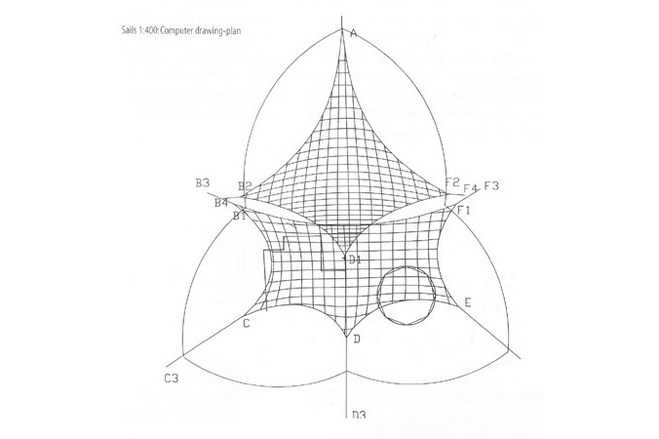

The roof structure is a self-supporting, tensile membrane. Membrane forces are carried by edge cables which run in membrane sleeves; corner plates and short tension members connect them to the masts. The guy cables of the masts proceed from the connection points of the sails to foundations in the ground and to concrete-gravity anchors under water. Two of the masts have four guy cables to reduce the bending moments resulting from the second sail and its forces, connected in the middle of the mast length. This results in a complex, three-dimensional mast structure. The outer corner masts C and E and the masts on the building's axis of symmetry, masts A and D, have two guy cables and carry one sail each. The two masts B and F on opposite longitudinal sides carry two sails on different levels, so that these masts are guyed by four cables .The welded tubular steel masts (Ø 273 x 5.0 mm to Ø 609 x 8.8 mm) were fabricated in one piece of galvanised structural steel St52 with mast lengths of 10.3 m to 22.0 m, with a welded mast head and gusset plates to receive the cable fittings. At the mast base the welded bearing assembly was equipped with an installation sleeve to simplify the introduction of the mast bearing into its bottom counterpart. The design windspeed is 47 M/sec (I 69 km/h).

Tension members

All tension members, i.e. edge cables, guy cables and membrane ties are stainless steel spiral strands (material grade 1.4401), which in parts were executed as twin cables for reasons of availability. Stainless steel cables, unlike galvanised cables, are not always available in all listed dimensions at short notice, often they are only available with long delivery times or must be specially made. A way out of this dilemma is to use available cable sizes (usually smaller cables are more easily available than larger ones) in a twin arrangement and with sufficient strength, of course.The guy cables and membrane ties are connected to the masts through welded steel plates and fork fittings.The lower ends of the mast guys are connected adjustably to twin stainless steel threaded bars (joined by steel spacer plates and embedded in the reinforced concrete foundations), by means of cable end terminals and stainless steel cross- heads made from square stainless steel bars.They are connected to the welded steel plate assembly of the mast head via swaged stainless steel fork terminals.

Foundations

Some of the tension foundations are below sea level in this tidal area of the Dubai Creek. At these underwater anchorages the threaded bars are long enough, so that the connection between cable and threaded bar is above the highest tide, and thus can never be washed over by the sea water. The underwater gravity anchors on the sea bottom are dug-in precast concrete elements; they consist of a concrete base plate with shaft rings above, which were filled with underwater concrete. In the area of the seating terrace the guy cables pass through a deck opening protected with a railing.

General comments, links

Membrane

The roof membrane consists of two overlapping sails, one with 5 and one with 4 corners, both of PTFE-coated glass fibre fabric. For technical and architectural reasons the sails are very shallow, resulting in fairly large membrane forces despite the relatively small membrane size. The edge cables are carried in membrane sleeves. They are connected with nuts and threaded stainless steel fittings to the membrane corner plates; the cable force is introduced through a short steel tube welded onto the corner plate. The membrane corners are composed of a lower triangular steel plate with short rolled steel brackets welded on to receive the U-bolt, a damping plate above and the membrane sandwiched in between and fixed in position with a stainless steel boltrope (or rather a bolt 'bar') inserted in a membrane pocket. The U-bolts are twin threaded bars with a steel plate welded in between.

[Soft Shells, Hans-Joachim Schock, p71, 72, 74]

Dubai Creek Marina Club, Dubai

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Godwin Austen Johnson

-

Engineers

Stromeyer & Wagner GmbH

-

Contractors

Stromeyer & Wagner GmbH

Editor

-

Editor

Marijke M. Mollaert