TEXTILE RIVER

General information

-

Location address

PARTICIPANTS' STREET IN EXPO ZARAGOZA

-

Location country

Spain

-

Name of the client/building owner

Sociedad Estatal EXPO2008

-

Function of building

Public spaces

-

Degree of enclosure

Open structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Sun protection

Description

Tensile fabric structures offer possibilities for the solution of urban problems which no other type of structure permits. In the Expo Zaragoza 2008 site (Saragossa, Spain) a 400m long structure has been designed that has turned out to be one of leading attractions of the event. It consists of thirteen pieces of torical surfaces that twist and turn at a height of 17m, taking on the appearance of a river. Technically, it includes some advances in structural geometry and artistically, it stands out due to its formal decoration.

With the aim of providing shade for the participants’ street we build a partial roof along the 500m of its length in such a way that no element would interfere with the views from the pavilions to the street or obstruct the route where various activities would take place.

This commission would not have been a problem in itself if it were not for the fact that several limitations existed. We could not place anchorages on the existing buildings because they were not dimensioned for it or in the public walkway as activities which require the street to be obstacle-free were foreseen. The structural and architectural solutions had to be completely stable in themselves with respect to horizontal loading because the pavilions could only provide vertical reactions. These limitations strongly conditioned the final design, which was arrived at by two different paths. The first was conceptual, and consisted in providing the project with a symbolic image. The other was structural, via which we searched for possible forms which would resolve their stresses internally and would convert them exclusively into vertical loads.

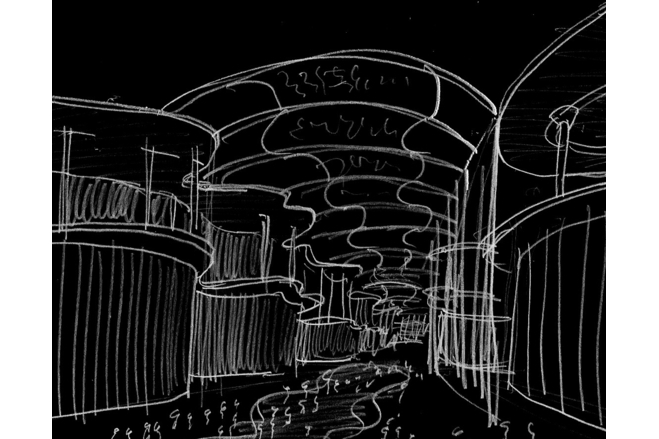

The conceptual idea consisted of using the exhibition's own leitmotiv, based on water, and building a river which flowed overhead and cast its shade onto the main street. Our objective was to represent Zaragoza's river.

The structural idea was based on a self-stressed system which resolves all pre-stresses internally and only transmits to the exterior the actions of gravity, snow and wind loads. We thought that a modular design would help in solving all the problems and modules of 32m x 24m were proposed, with a central part of these comprising 14m x 32m of textile. To prevent the repetition of 13 of these modules from being monotonous, they were mounted in such a way that they curve, as though it were the meandering of a river bed.

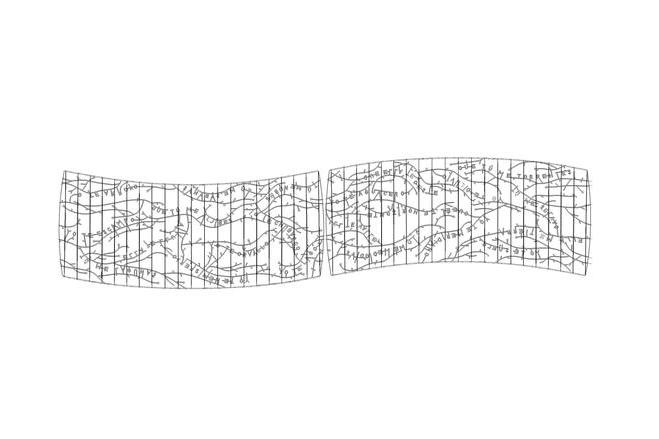

In order to round off the idea, the textile roof is covered with artistic patterns, which we consider to be a plastic work which combines technique and design, as can be seen in the pictures of the finished project. We wanted the architectural image to be complemented with a design by one of the country's most important artists, in this case Isidro Ferrer.

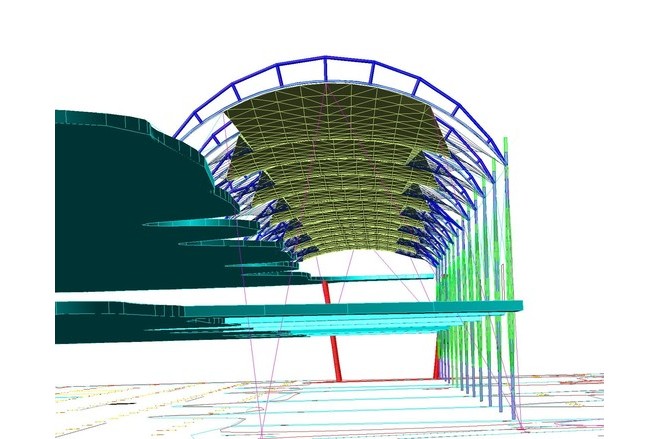

Our main challenge was to achieve a support for the textile fabric surfaces capable of functioning in a self-stress state, that is to say, with vertical reactions exclusively. The horizontal reactions typical of these kinds of structures and arches were avoided with a disposition, where tubular metallic arches would be stabilised by tendons on the upper part of the arches and by cables below them. It is precisely the introduction of these upper tendons which has been special for this project, since an arch is considered to be stable when it cannot open by an outward horizontal thrust, and here the arch cannot expand because of the lower cable, but with respect of the action of the fabric we have also prevented it from closing inwards as it cannot increase its curvature due to the upper tendon. The lower cable works with pushing loads and the superior tendons work when pulling loads are acting.

A succession of fourteen arches set at 32m intervals leaves thirteen zones in which modular roofs can be drawn taut. The covers are designed to be seen and to be used as a continuous canopy over the street.

The tensile fabric structures used are surfaces of toric geometry (the inner part of a doughnut), 14m wide and 32m long, as mentioned above. The pieces used are limited by two vertical planes and two curves with circular projection.

In order to support the curved fabric borders we placed curved steel cable edges at the exterior, which are the fundamentals of the entire structure, as between the self-stressed arches and these border cables or “bolt ropes” (curved edge cables with bolts) a highly resistant fabric is tensioned, which defines our overall design.

In order to complete it we dispose another series of cables and rods which are fundamental for the functioning of the assembly but which are barely visually perceptible.

The way the arches are supported along the axis is different on the right and on the left side. On the right, they are connected to the roof of the pavilion buildings while, on the left, they are connected to the top of 17m high masts.These masts are of variable cross section and are pinned at their base so as to easily absorb the twisting and bending movements typical in these types of supports for light structures. Masts and arches are rigidly connected, more to facilitate construction than to transmit bending loads.

Horizontal stability of the masts is guaranteed by diagonal cables for the longitudinal direction which prevent them from turning over, and with the arches in transverse direction.

On the roof, arches are supported directly on the post-tensioned concrete slab at the points where there is a concrete support directly below or on a steel laminated rod to avoid encountering the heads of the tension cables of the concrete slabs. These supports are dimensioned to carry almost exclusively vertical loads and only some small occasional horizontal forces.

The arches tensioned on their lower side with a cable and on the upper side with a combination of sticks and tendons are constructed in a polygonal curve made with segments of 400mm x 200mm rectangular pipes where the tensile fabric, interior cables and edge cable devices are connected to. Because the street is not uniform in width not all of the arches are equal. There are two types: arches with a 24m span and arches with a span of 32m, although all of them have the same height of 6m.

In order to make the edges of the textile taut a succession of parallel cables was added and connected to a border comprising two parallel cables in a parabolic curve, resulting in a technological solution. Generally speaking, we try to make our designs completely stable in themselves, even when the textile elements are absent. In this way, even if a textile cloth had a structural defect this would not imply the collapse of the rigid elements.

Everything that has been said about a self-stressed system works for the interior modules, but not in all aspects for those at the beginning and the end of the street. This is because there are horizontal forces here that can only be absorbed by means of anchorages to fixed points with the transmission of important horizontal components. In order to solve this problem of equilibrium we ran inclined cables to fixed points on the foundations, as can be seen in Figure 13. We chose to connect at places where there were already other types of supports so as not to increase the number of obstacles in the street. On the other hand, as the loads from these cables are tension forces, the performance of the foundations is improved at the points where the walkways between pavilions are supported.

The role of the roof is not exclusively functional - providing shade - but it is also an important part of the functioning of the structure. When we installed the textile modules we achieved a total equilibrium of stresses where none of the elements is superfluous and each is indispensable. Nevertheless, certain considerations need to be taken into account with this kind of architecture in tension, and are worth emphasising as design principles:

1. Despite its high resistance under tension, the textile has very little resistance to tearing and rips can occur at the joints. When this happens stability is only lost between cables and the rest remains in place, and normally in good condition.

2. The textile meshes are designed in such a way that they maintain self-equilibrium when the textile is not in place, that is to say, that the absence of textile does not imply either the fall of cables or the collapse of rigid elements.

3. These types of modular structures have to keep functioning even in the absence of a module, whether it is interior or exterior.

4. The stability of these structures is based on the fact that they are in a state of strong internal tension, which we refer to as pre-tension, before starting to introduce any exterior load.

5. The external loads, basically due to the wind, can act in a different way on each element at each moment in time.

6. The wind loads concentrate their energy in gusts and are thus dynamics of very long periods, between 0.5 and 2 seconds, which means that their movements are visible and therefore disturbing. The greater the initial pre-tension to stabilise the whole, the shorter will be the period of vibration.

7. The forms that can work for this type of roofs are warped. This means that they cannot be constructed from flat surfaces except with an adequate cutting pattern. In our case, we opted for a cutting pattern of a transverse type which takes full advantage of the commercial reel width.

All these aspects have been taken into consideration in the construction and structural composition of this roof.

Along with those already shown in previous figures, Generally speaking, the construction details of this type of cover have been studied in depth and we have turned to previously-known solutions, although a certain degree of innovation is always necessary. Thus the “bolt ropes” (curved edge cables) are resolved with double cables in order to tighten the cables which pull the textile taut and the superior screw threads of the arches are resolved bit by bit by means of a nut at each end.

One of the most important aspects of a textile roof project is to program the sequence of assembly and tensioning. In this case we chose to stress the entire metallic mesh previously, apart from the stressing which depends on the existence of the textile. Then it was possible to mount and stress each module in turn, which greatly facilitated the construction process. Moreover, it has been necessary to work in a space full of obstacles, and without priority over other work in the street as far as assembly was concerned.

Once the assembly is completed it is necessary to proceed to introduce tension into the fabric until achieving nominal design stress. This is difficult to check in the cables and even more so when it comes to the surfaces. The mechanised techniques which exist for this are not very trustworthy and it is better to operate by approximation on the basis of the reactions as, in the absence of external loads, the overall result suggests an equilibrium which is easy to check. The force applied via the screw threads at the extremes determine what happens in the interior in the absence of wind. For this reason, if we check the reactions of the few anchoring cables we have on the exterior we will be able to make an approximate estimation of what happens to the whole.

The analysis of this structure is really quite complicated due to its extension and owing to the nature of its components. Moreover, it is difficult to evaluate the loads and the simultaneity of their action. It is for this reason that we have made separate calculations for the textile elements and the metallic ones. In this way, the surfaces, along with their edge elements, have been analysed using the SAP2000 programme in order to obtain some generic stresses. The supporting elements, meanwhile, have been dimensioned with these previous reactions in order to obtain some stresses and reactions which have served to dimension the entire structure. Without entering into further detail, the loads which have been taken into consideration are wind loads when the wind is blowing at 100 km/h, and snow has not been taken into consideration as this roof will only be used during the three months that Expo 2008 lasts.

Posterior to the construction, wind speeds of up to 90 km/h have been measured without appreciating any alterations in the structure, which has served as confirmation that it is an appropriate and successful design.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

ferrari 392

Main dimensions and form

-

Covered surface (m2)

5000

-

Total length (m)

400

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Felix Escrig

José Sánchez

-

Engineers

Performance S.L.

-

Contractors

IASO S.A.

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Evi Corne