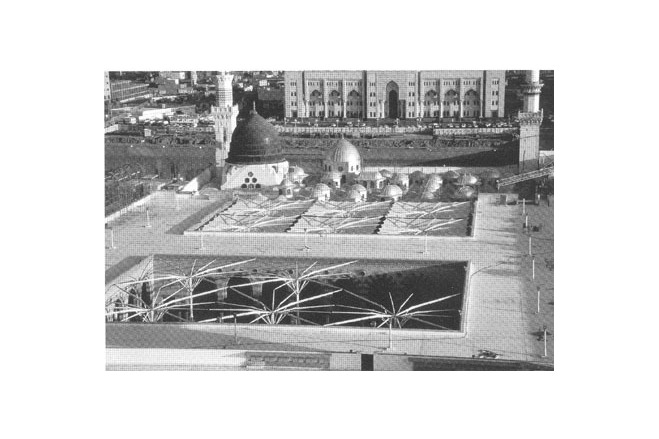

Climate-Control Parasols for the Extension to the Prophet's Holy Mosque 1992 - replacement and extention 2012

General information

-

Location address

Medinah

-

Location country

Saudi arabia

-

Year of construction

2012

-

Name of the client/building owner

SBG Saudi Binladin Group, Jeddah

-

Function of building

Religion

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Arid - dry and hot all year

-

Number of layers

mono-layer

Description

Design

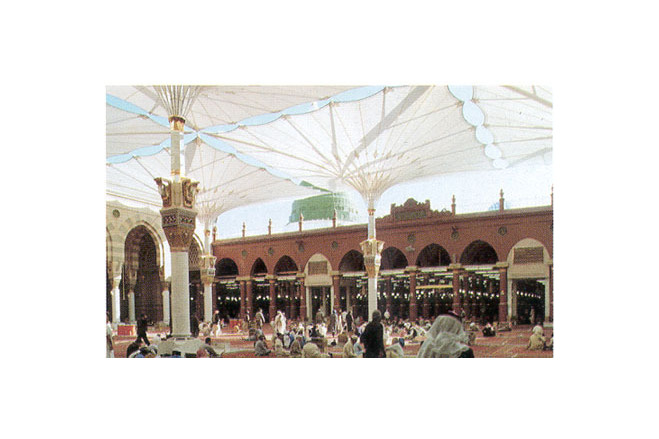

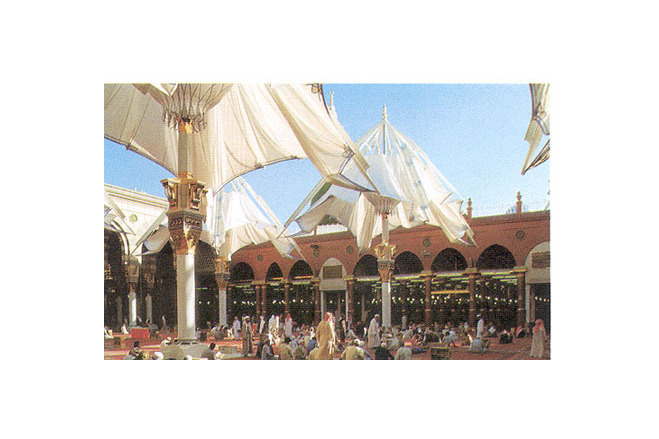

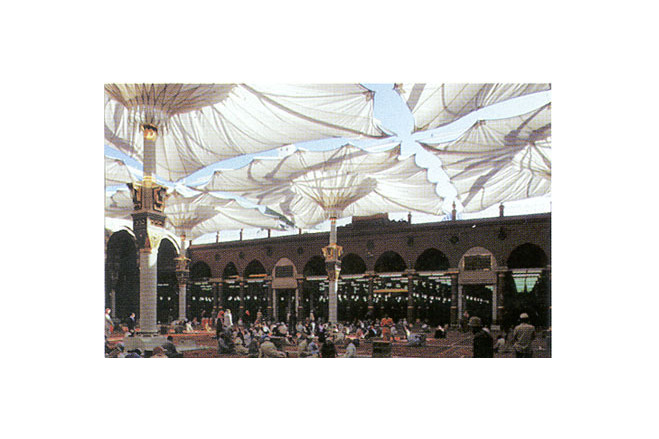

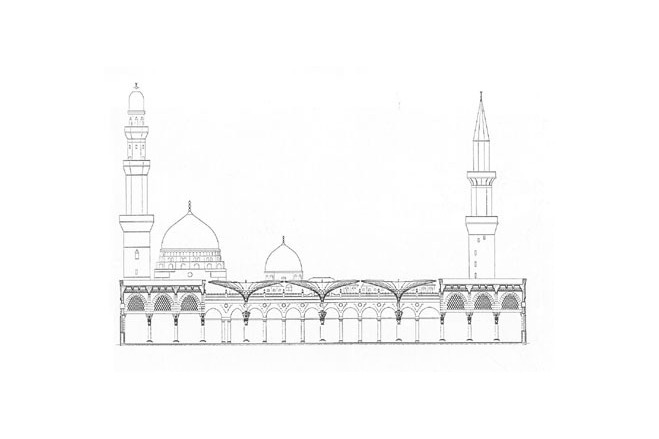

The commission to design a convertible shade roof for two large courtyards of the Holy Mosque of the Prophet in Medina presented an unusual architectural and technical challenge. At this location, where tents of thousands of believers gather every day, the climatic conditions had to be improved without destroying the character of the open quadrangles and their familiar environment.

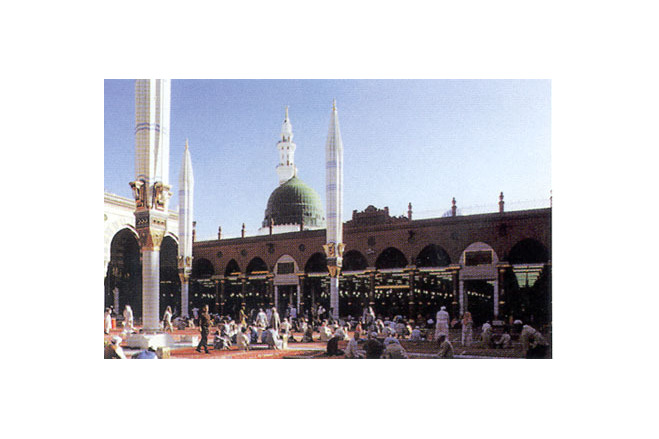

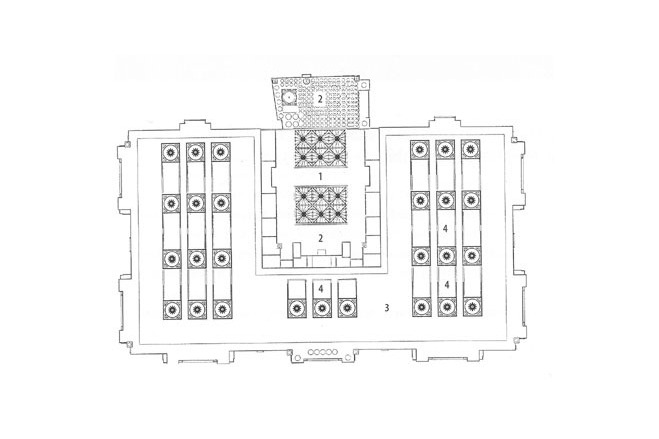

The solution consisted of twelve convertible parasols, 17m x 18 m large and with a height of 14 m at the eaves in their opened condition, which fit in perfectly with the proportions of the courtyards. With a span of 24 m, measured diagonally across the corners, they are the largest ones built of this kind.

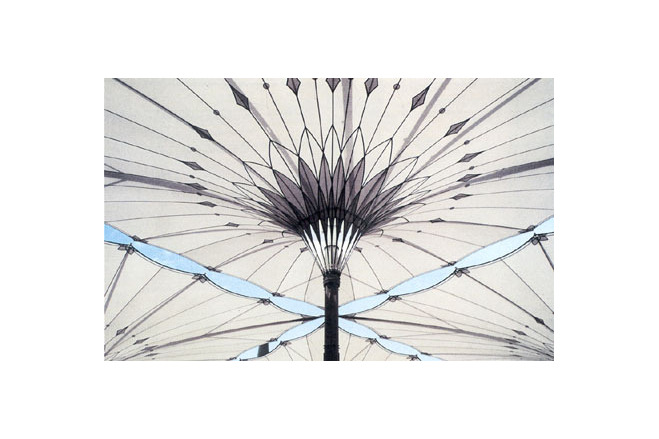

The six parasols with their funnel-shaped membranes create the effect of translucent vaults, spanning between the columns and the arched arcades surrounding the courts, and produce a large free space. Their timeless form with its carefully designed ornaments match harmoniously with the traditional architecture.

Technical installations

Air conditioning

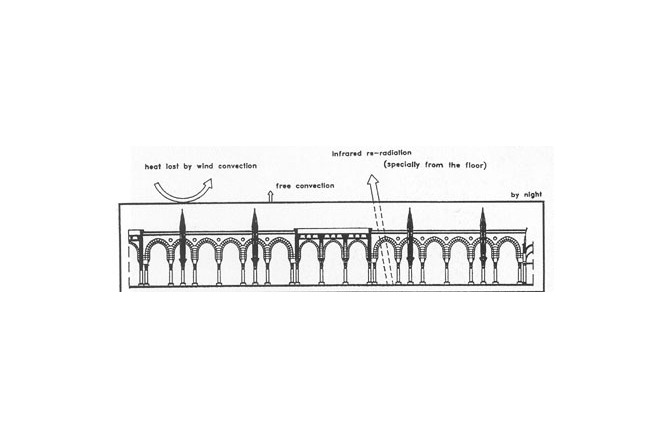

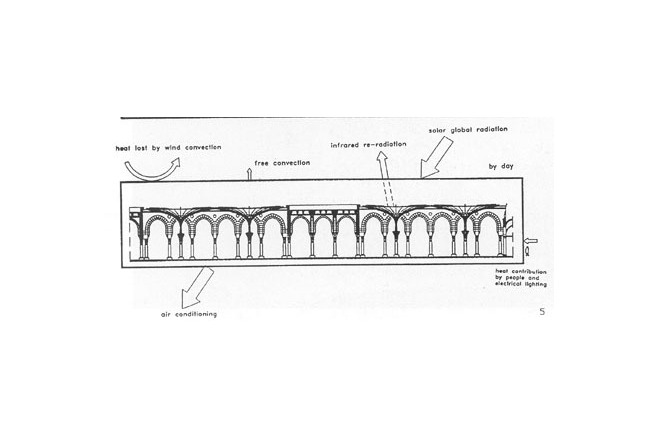

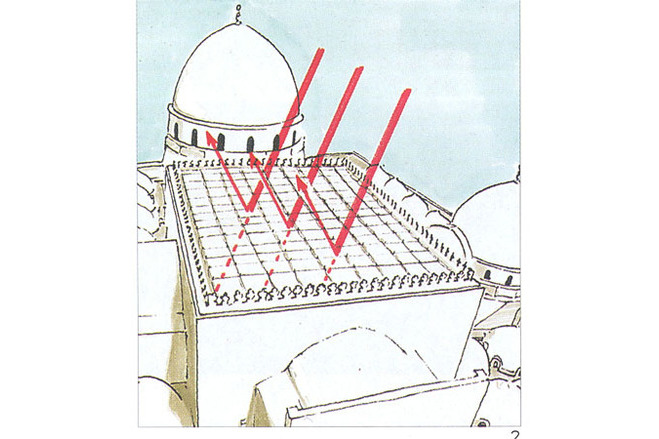

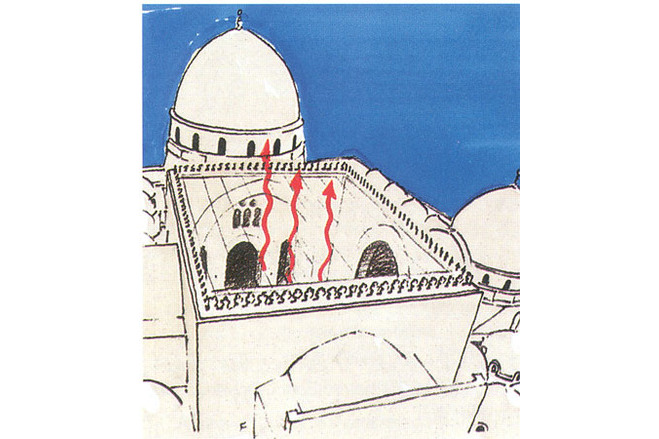

Through controlled use of this variable roof structure extreme climate differnces can be equalised, modifying the climate inside the building and reducing energy consumption. In the summer the opened parasols offer shade during the day, when the white PTFE-membrane re-emits a large proportion of the solar radiation to the outside. At night, in a closed position , they allow the thermal energy stored in the heated building surfaces of the courts to escape unhindered into the night air.

In winter, when the median temperatures are relatively low, the parasols are opened during the night to prevent an extreme cooling of the building; they are closed during the day to admit the mild winter sun and so to warm the building's surfaces and masses.

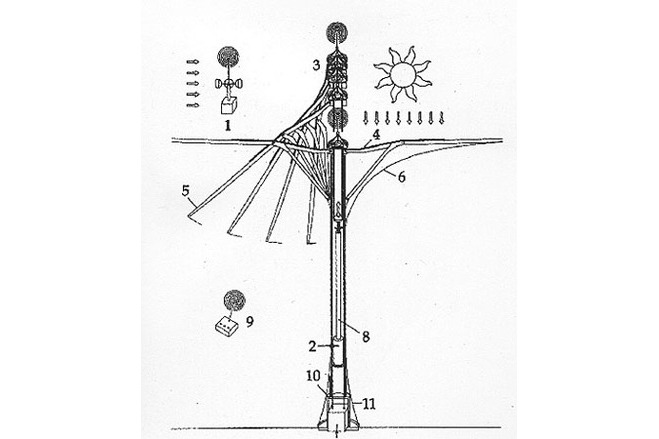

Opening and closing times of the parasols are computed electronically for every day according to the position of the sun, dependent on the seasons, and allowing for weather conditions, outside temperature, wind and cloud cover and the results fed into the parasol controls. To make the climatic conditions in the courtyards more comfortable during the summer months, when the air temperatures in the shade can exceed 45°C, the parasols' controls are coupled with the bulding's air-conditioning system. Air outlets in the base and the capital of the parasol column distribute cool air noiselessly in a wide area, so that the entire quadrangle is cooled evenly and effectively.

Drainage

When it rains, the rainwater is drained via the funnel shaped membrane and through the column into the floor drain.

Lighting

Each parasol has four strong lights installed in the cladding above the column capital, which illuminate the quadrangles at night.

Replacement and extension in 2012

The excellent experience with the technical and architectural performance of the 12 umbrellas (17m X 18m each) that are shading the two large courts at the 1st Saudi Expansion of the Prophet’s Mosque in Madinah since 1992 encouraged the client to decide for the proposal to install additional a total of 250 umbrellas (26m x 26m each) at the large Piazza surrounding the Mosque. This arrangement of large umbrellas is covering all together an area of about 150.000m² to offer shaded space for prayer and for safe circulation for about 350.000 to 400.000 people during the pilgrim seasons in Ramadhan and Hajj. This extraordinary convertible membrane shading roof is the largest one built and is an innovative architectural solution for an outstanding task without any reference or sample. Lightweight architecture to provide a most distinguished space and climatic comfort supposed for people coming from all over the world to visit the Prophets Mosque in Madinah.

Description of the environmental conditions

Structure

The components of the parasol structure, mast column, arms and struts, are a welded construction of a high-strength fine grain steel.

For good precision of the movements the bearing bores of the critical hinges were made by a (computer-controlled) NC-milling machine. This manufacturing precision of the movable parts together with the placement of the hydraulics pumping in a central plant makes an almost noiseless working of the parasols possible.

Foundations

The reinforced concrete pad foundations of the parasols are joined with each other by ground beams.

Mechanics

The parasol has altogether 20 arms: four long diagonal arms with two short passive arms each connected to them, eight middle arms, of which four are shorter and four longer.

The parasol is opened and closed by a hydraulic cylinder on the column axis, whose upper end is pin-connected with all the active arms. In the closed condition the hydraulic cylinder has driven out completely at the top; to open the parasol it drives down, whereby the struts, which are pinned above the capital, push the parasol arms, which are connected at the upper end of the hydraulic cylinder, to the outside, prestressing the parasol membrane. The electronic controls and hydraulic pump are housed in a central controls room in the basement and connected with the 12 parasols via high pressure pipes under the marble floor of the courtyards.

Protection flaps

In designing the parasols special care and consideration was given to the closed condition and to the folding of the membrane. Pin-connected protection flaps of especially lightweight carbon-fibre-reinforced resin laminate are fixed along the diagonal arms.

They are moved by a mechanism of struts and hinges installed in the arm and driven by the arm movement. They close around the membrane, when the parasols are closed. When the parasols are closed these protection flaps, together with the fixed sheet flashing in the upper part of the arms, form a stiff envelope for a light fabric membrane.

Loads

Wind tunnel tests for the specific situation in the courtyards served as a basis for the design of the structural elements of the parasols, which were designed for the opened and closed condition using a wind speed of 155 km/h. An anemometer connected with the central controls prevents the opening and closing at wind speeds above 10 m/sec (36 km/h).

Membrane

The funnel-shaped membrane is made from white PTFE-fabric. Edges and ridges are reinforced by a webbing. The underside of the fabric is decorated with ornaments in blue colour. The fabric was developed specially for this project, its thread thickness and type of weave were modified repeatedly, until all structural and mechanical requirements on strength and durability were fulfilled. The material is resistant against UV-radiation, chemicals and fire, has a low surface friction and is therefore a near-ideal material for convertible sun roofs.

[Soft Shells, Hans-Joachim Schock, p153, 156, 157]

General comments, links

Architectura & Natura

Bodo Rasch: Architectural Umbrellas

Climate-Control Parasols for the Extension to the Prophet's Holy Mosque, Medina, Saudi Arabia

Architex - des idées nouvelles pour une construction nouvelle

Teil 9/21: Schirmkonstruktionen für die Al Haram al Shareef Moschee, Medina

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Ptfe

Main dimensions and form

-

Covered surface (m2)

300

-

Total length (m)

17

-

Total width (m)

18

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Mobile

-

Design lifespan in years

11-20

Involved companies

-

Architects

SL Rasch GmbH

-

Engineers

Buro Happold

-

Contractors

Koit High-Tex GmbH

Editor

-

Editor

Marijke M. Mollaert