Canivore and Palm house, Munich Zoo

General information

-

Location address

Munich

-

Location country

Germany

-

Name of the client/building owner

Münchener Tierpark Hellabrunn AG

-

Function of building

Entertainment & recreation

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

Description

Design

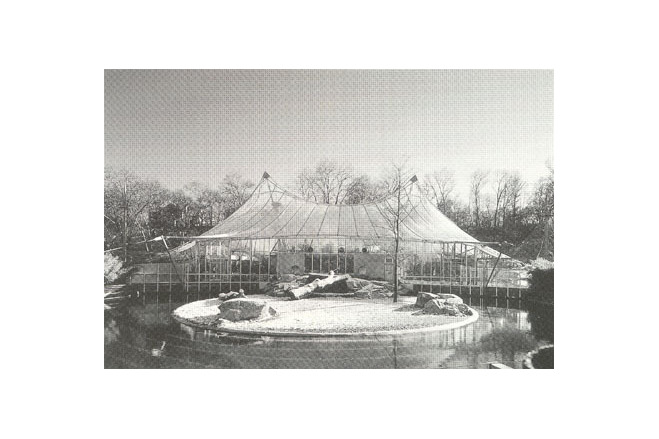

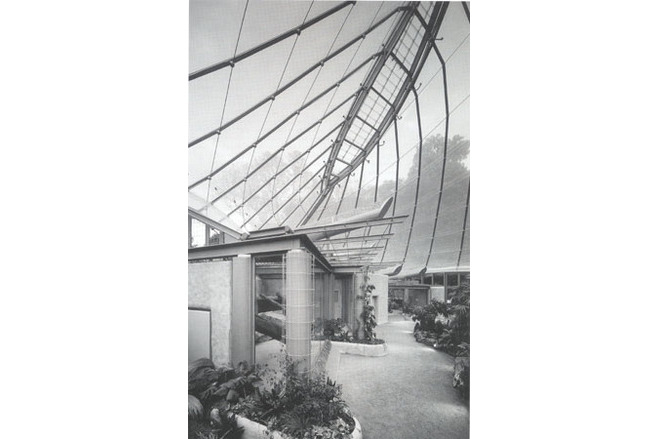

A novel zoo concept: In the 'jungle tent' visitors as well as small apes and birds can move around freely in a natural setting. Separated only by glass panes from the visitors, the animals can be observed as if they were in a forest glade. A little stream with waterfall, walk-on 'hills' and sumptuous tropical and subtropical vegetation create the impression of a visit to the jungle. For the natural growth of the plants and their protection from parasites and diseases maximum levels of UV-light are necessary; and the minimum temperature may not drop below 12°C. These considerations soon led to investigations of wide-span structures and transparent cladding. In several design steps the solution of a cable-net roof emerged with a cladding of pneumatic foil cushions. An alternative cladding system exploring overlapping small polycarbonate panels (of the kind used on the concert sail in Radolfzell) had to be excluded because of its large air-permeability and the resulting unsatisfactory thermal insulation.

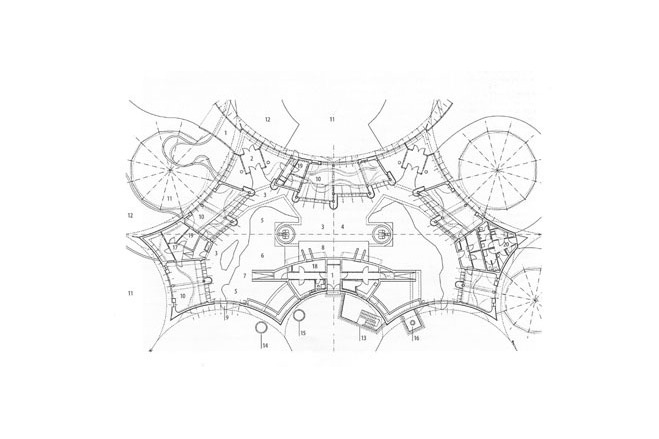

Situation, plan

The construction site is situated in Munich Zoo at the foot of the Harlaching hill in a landscape protection zone, in direct proximity of the historically important and listed elephant house of 1911. The building has an octagonal plan defined by curved edge cables; it is symmetrical about one axis. Its covered plan area is 1140m². Two visitors' entrances furnished with air locks are situated on the north-west side. The animal boxes for lions, panthers, jaguars and other large carnivores are arranged along the facades, some of them having access through the façade into open-air enclosures. On the longitudinal side facing the entrances lies an artificial planted hill, under which a number of bird boxes and other ancillary rooms are located together with the delivery entrance. In the middle part, on both sides of the mast foundations, there is a plant area without underlying ground slab.

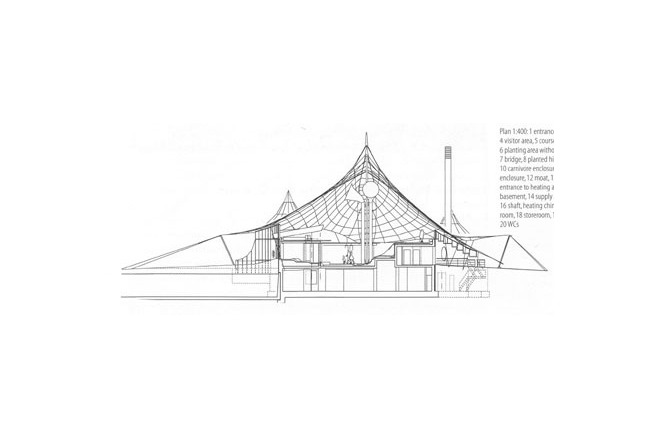

Structure

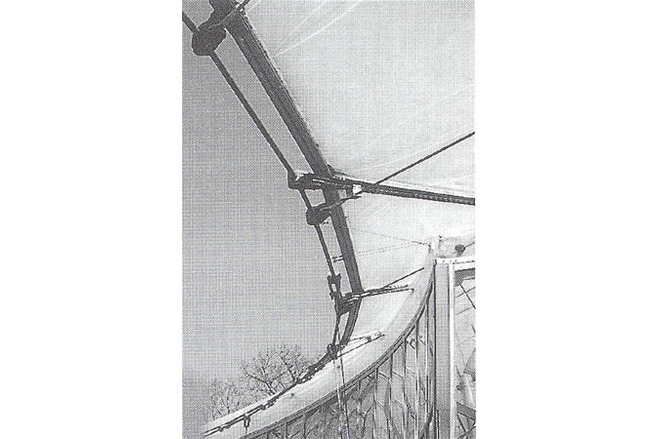

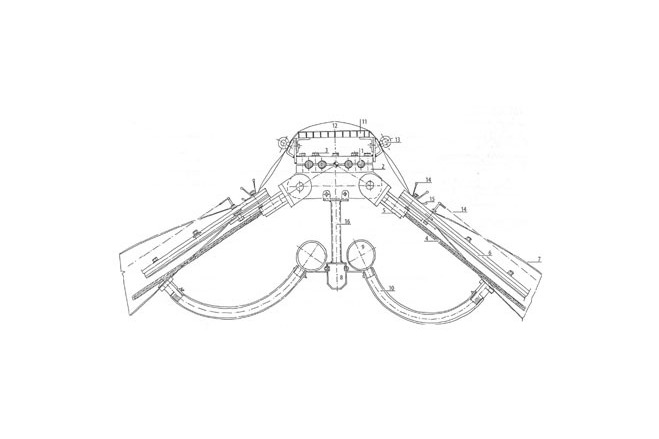

Two 17-m high masts carry the prestressed net structure made from high-grade steel cables with a mesh width of 2 x 2 m. It is supported on two cable-braced tubular steel masts; a straight compression tube is stabilised through a three-chord tie bracing of round steel bars with star-shaped spreaders made from short compression struts arranged along the mast length. At the mast head the ridge and eye cables are connected , which at the same time laterally support the mast tip. At the base the masts are pin-supported on the reinforced concrete substructure. The edge masts consist of simple tubular steel columns.

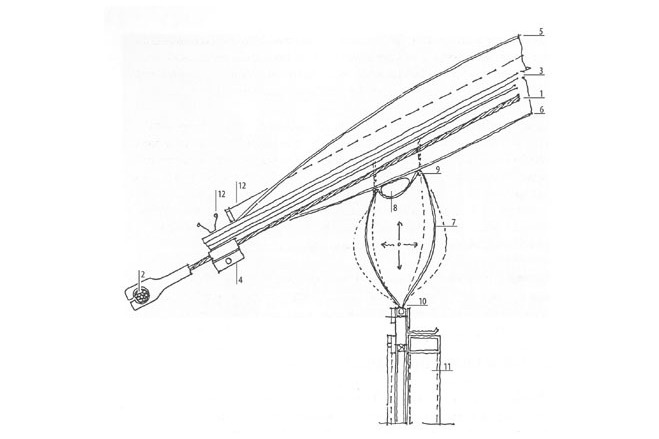

Façade connection

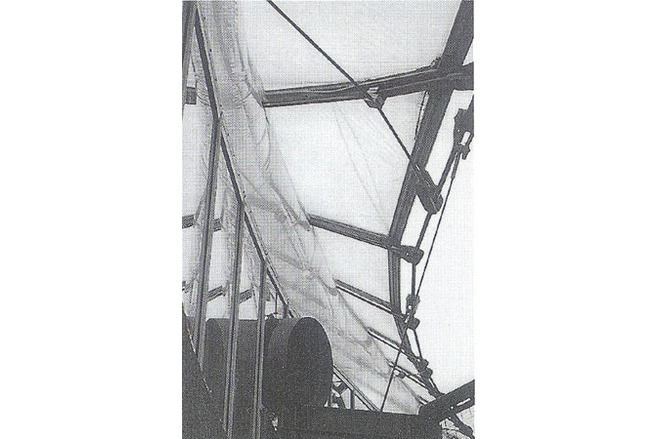

The wind and rain-proof connection of the foil cladding with the heated steel and glass façade must be able to tolerate large deformations of the roof, e.g. under snow load. The connection is made through curved tube cushions, which are fastened to the upper edge of the façade, held in position with cables and pressed against the roof cushions by their inflated pressure. In addition to the air supply controlling the pressure, relief valves are installed, which open at a sudden pressure increase under load and thus allow a fast pressure adjustment. A further internal sealing tube, running parallel to the edge belly cables provides an almost perfect air seal and at the same time prevents the escape of small tropical birds.

Description of the environmental conditions

Cable-net

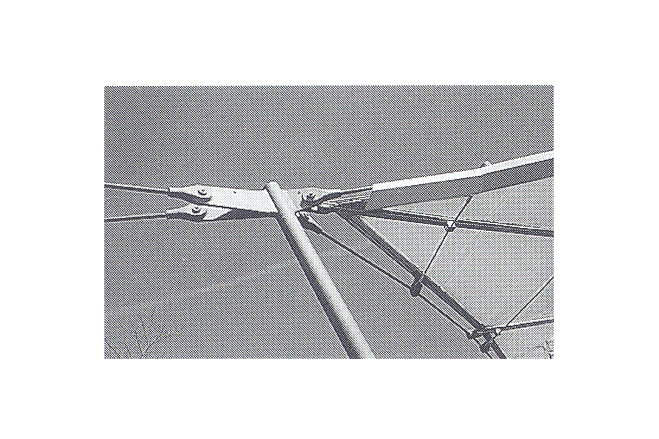

The roof is a symmetrical cable net surface with two inner high points (H = 17 m) joined by ridge cables. The structure is a radial cable net made from radial and hoop cables. It is composed of double radial cables (Ø 18 mm) and single hoop cables (Ø 16 mm); at the top it is supported by four ridge cables (Ø 32 mm), held at the edge by edge cables (Ø 36 mm) and anchored at its eight corner points by masts, guy cables (Ø 36 mm) and injection anchors. Snow loads, if they are not melted already by the warm air, are carried by the internal pressure into the lower foil of the pneumatic cushions and into the radial cables of the net, which introduces its load mainly into the ridge cables connecting the masts. The statutory snow loads to DIN 1055 were fully allowed for in the structural calculations. Wind loads are carried by ring and radial cables into edge cables and substructure. The net cables are joined through movable high-grade steel cable clamps, onto which the edge clamping arrangement of the cushions are fastened. The cushions have been developed into cutting patterns along edge and surface seams and are connected via a boltrope edge and by special aluminium-edge profiles to the cross clamps of the cable net and to the edge cable clamps. The cable clamps of radial and ring cables are connected with a central bolt and are free to rotate, so that the mesh angles can adjust freely to adapt to the three-dimensionally curved cable-net surface.

The net edges are 3,5 m above the ground; there the net cables are equipped with a swagged closed cable fitting which is pin-joined through a flexible one-bolt connection with two forked connecting elements, which in turn are fastened to a two-piece, circular edge cable clamp. At the net corners the edge cables are connected via fork fittings directly to the head plates of the edge masts.

The four ridge cables running from one mast head to the other are joined at the junctions with the radial net cables through a welded cable clamp. The net cables are connected to its lower plate stiffener by a swaged fork fitting and a flexible one-bolt connection. Under the ridge cable and suspended from it run a cable tray and the supply pipes for the pneumatic cushions. The ridge is closed on top through a grating, serving as a service walkway, and by a double-layer of ETFE-foil above it connected with the membrane cushions along their edge. This unorthodox solution allows walking on the ridge and at the same time provides a transparent an thermally insulated ridge covering. The ridge cables are continued on the other side of the mast down to edge guys, forming eye shaped openings, which are closed with mechanically operated ventilation louvres.

Assembly

For the installation of the roof structure scaffolding was erected in the interior, from which most of the work could be accomplished. After positioning of the masts the cable net was assembled on the scaffolding from single cables connected at the nodes by cable clamps and raised gradually. The net was prestressed from ridge and edge cables to 8 anchor points. The prefabricated cushions were fixed first along one side of the High-Tex cushion profile, rolled out sideways, tensioned and finally fixed on the other cushion side. The edge areas inaccessible from the scaffold had to be worked from the net. The entire construction period totalled 3 years.

General comments, links

Foil cushions

The foil cushions are composed of two flouropolymer foils (t = 0,2 mm). The foil material, ETFE (Ethylene Tetra Flour Ethylene) is anti-adhesive, highly self-cleaning and is classified as 'difficult to ignite' (class B1 to DIN 4102). Its durability has been shown through long terms tests, and according to company information, shows no (considerable) changes of optical or mechanical properties after 10 years of natural weathering. The translucency of the roof structure in the waveband important for plant growth total approx. 90%. The translucency of the foil itself in the UV range amounts to 96%. The 64 wedge-shaped cushions (max.b = 2,5 m, max.l = 18 m) are filled individually with dried and purified outside air via separate, flexible and closable cushion feeds through a pressure pipe running along under the ridge, which helps to prevent condensation and to preserve the translucency of the cushions. The inflation pressure varies according to the external loading, wind and snow, and is controlled by a computer system, which can compensate minor damage of the membrane through a pressure increase. The pressure normally amounts to 250 pa and can be increased to 350 pa if required. For the inflation of the cushions altogether 4 fan units are provided, with one main and one reserve blower. The latter serve to ensure the safe working of the system even in case of breakdown of a main blower, and also serve to increase the air volume in case of breakdown of a main blower, and also serve serve to increase the air volume in case of damage to the membrane. The air supply is controlled centrally using an anemometer located at one of the masts.

The aluminium edge sections which hold the transparent foil cushions at the edge proceed from the ridge radically down to the lower net edge. These High-Tex-aluminium extrusions (consisting of three principal aluminium extrusions and an extruded cover strip section) are bolted directly onto the radial cables. The ring cables are connected with a spacer piece to the radial cables unerneath and are located under the foil cushions, so that these can deform unhindered under the load. The 'belly cables' common in earlier cushion structures were not used here. (They are, however, used along the edge, to hold the sealing tube in place).

Ventilation

On two sides of the masts ventilation ducts proceed to the air intake funnels located at the mast heads. In the winter months these air intake funnels serve as forced ventilation. As the free-flying tropical birds in the jungle tenet are very draft-sensitive, the air speed had to kept much lower than in similar ventilation systems. Through the funnel shape the air cross section is expanded which decreases the air speed. According to the HVAC calculations a 10,5-fold air exchange per hour is sufficient for the single cell cushion roof, so that even given extreme outside temperatures the inside temperature does not move outside the required tolerance band. During the summer months the building is ventilated by natural stack effect through two large net openings. They consist of lens-shaped areas cut into the membrane and closed by acrylic glass louvres individually supported by stainless steel brackets sealed to each other. They can be moved continuously and have their aperture angles regulated electronically. The system can be opened so that the entire net eye area is available as a ventilation opening.

[Soft Shells, Hans-Joachim Schock, p62, 64, 66]

Carnivore and Palm House, Munich Zoo, Germany

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

ETFE-foil

Main dimensions and form

-

Covered surface (m2)

1140

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

IPL Ingenieurplanung Leichtbau GmbH

-

Contractors

Koit High-Tex GmbH

Editor

-

Editor

Marijke M. Mollaert