Prince Mohammed Bin Abdulaziz International Airport (PMIA)

General information

-

Location address

Medinah, Saudi Arabia

-

Location country

Saudi arabia

-

Year of construction

2015

-

Name of the client/building owner

TAV Construction and Al- Arrab Contracting Co.

-

Function of building

Airports

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Daylight gains

- Space defining elements

- Sun protection

Description

Introduction

Madinah is located in Western Saudi Arabia. It is the second holiest city in Islam after Mecca and the first capital of Islam. The city, hosting the tomb of Prophet Muhammad, is an important destination for religious tourism and attracts each year a large number of pilgrims. The passenger traffic at the airport increased by approximately 21% to 5,7 million passengers in 2014, compared with 2013. The increasing number of passengers led to a phased expansion and rehabilitation of the airport.

Design

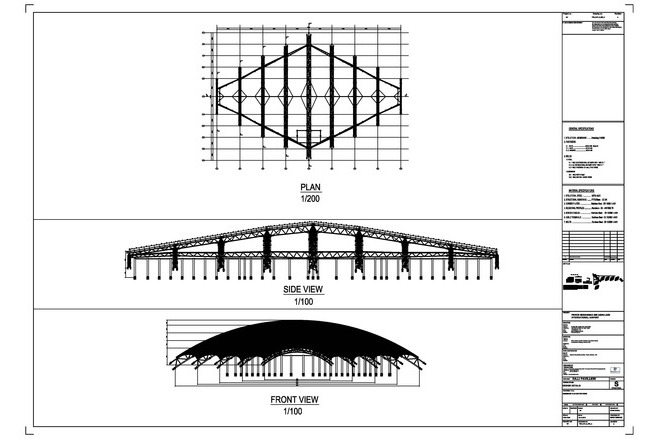

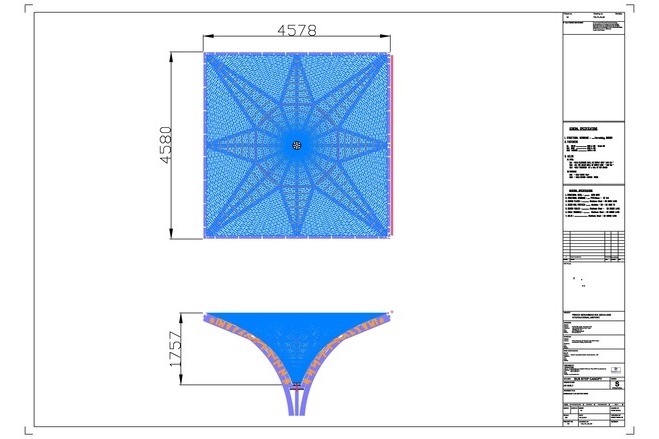

The first phase of the expansion includes the construction of a new passenger terminal building. The architecture is well integrated into the existing infrastructure of the airport. The design of airport’s expansion over three phases was made by the GMW Architecture. Their design concept was inspired by the airport’s role as a gateway for millions of Islamic pilgrims and the palm tree, symbol for peace and welcome, has become emblematic in the terminal building. This palm frond was the main source of inspiration for the architectural form and it provides an efficient structural support.

The geometry of the grand canopy refers to the structure of an octagonal family of radiating, intersecting and concentric line-work in resonance with the symbolic working of Islamic geometries and focuses on elegant, modular and spacious interiors. The new terminal and airport is built to the highest international standards and allows an initial operating capacity of 8 million passengers per year.

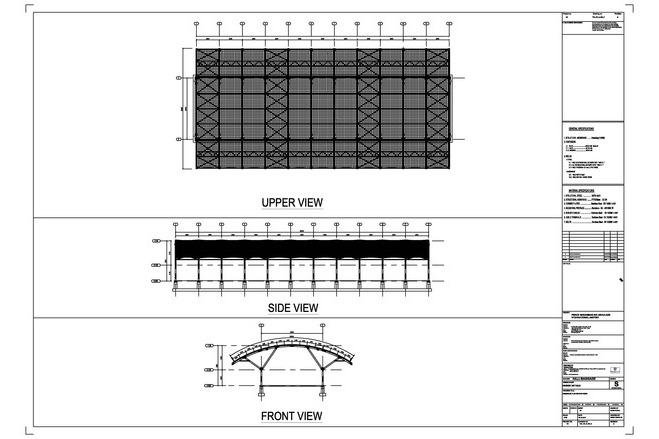

Textile roofs

Tensaform was involved in the engineering, manufacturing and installation of different textile roofs: Ministry of Hajj Roof, 6 units of Hajj Pavillion Building Roofs, Hajj Baggage Roof, Masjid Courtyard Palm Canopy, Hajj Area Walkway Shading Vault Shade, Bus Stops Palm and Vault Canopy, Carpark Single and Double Module Shade.

Tensaform has chosen for these roof coverings the membrane PTFE Type III B 18089, manufactured by Verseidag – Indutex. A membrane surface of approximately 47.318m² was manufactured by Tensaform at its manufacturing factory, located at Malkara. A team consisting of around 5 technican guys as engineers and 30 supervisors completed the installation. [TensiNews 30 - 2016]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Type (code)

B 18089

-

Material Fabric/Foil

Glass fabric coated PTFE

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

47318

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

21-30

Involved companies

-

Architects

GMW MIMARLIK

-

Engineers

Tensaform Membrane Structures Industry & Trade Inc.

-

Contractors

TENSAFORM MEMBRANE STRUCTURES INC.

-

Suppliers

Verseidag-Indutex GmbH