APPP Church - a double layer insulated membrane covering

General information

-

Home page

www.tentech.nl

-

Location address

Maassluis

-

Location country

Netherlands

-

Year of construction

2007

-

Name of the client/building owner

Andreas Paulus Petrus Parish

-

Function of building

Religion

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

multi-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Space defining elements

- Thermal insulation

Description

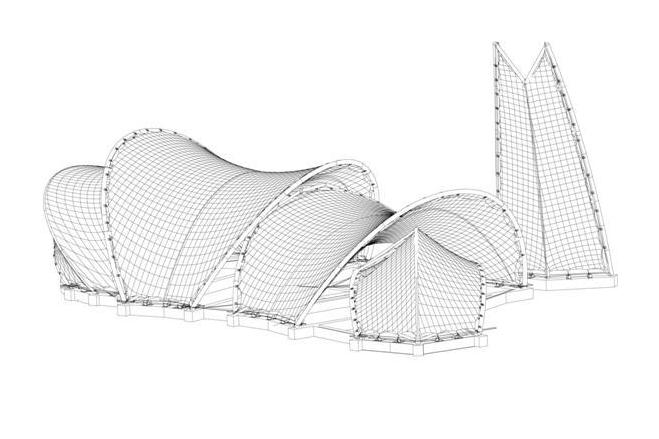

APPP church with double layer insulated membrane covering

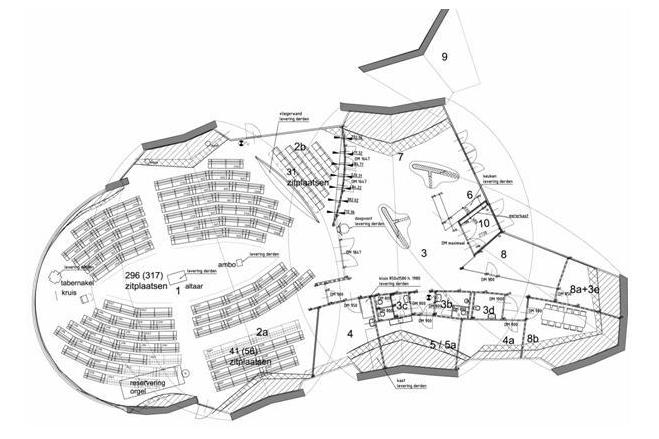

For the Andreas-Paulus-Petrus Parish at Maassluis in The Netherlands, architects Mari Baauw and René Olivier of Royal Haskoning made a design for a new church. In the past, different layouts of a church have been developed, each layout having its own effect on the liturgical process in the church. It is restrictive to choose one layout as a basis for the design. Here, the design is based on an innovative functional layout. The architects have chosen to introduce the concept of segmentation: the segments should act horizontally and vertically, wide, deep and high and should be large and small at the same time. Moreover, it should feel comfortable for groups as well as individuals and it should become a space that breathes.

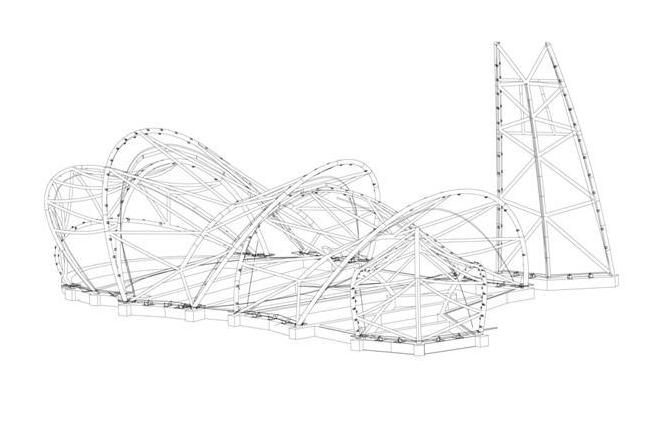

These conceptual ideas were transformed into a physical model based on five different shells grouped together, partially overlapping each other. By doing so, the aforementioned segmentation was possible. The daylight enters the building between the overlaps of the different shells.

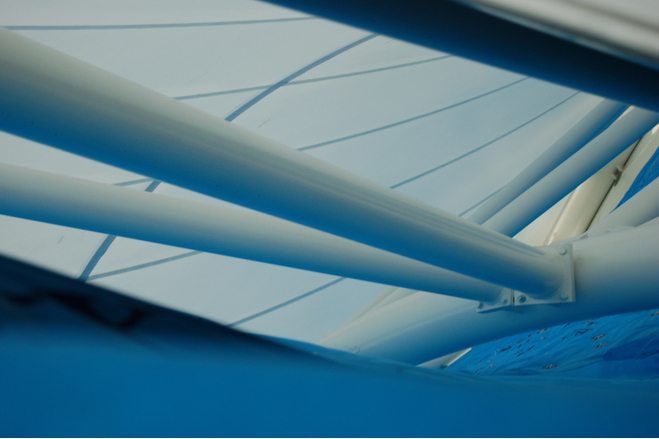

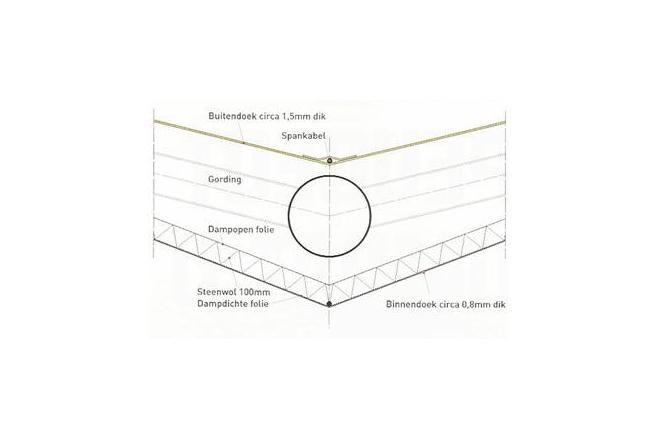

The design by the architects was merely based on the functional requirements of the spaces, meaning that there was no materialization of the design. So the starting point for the structural design was the physical model of the architect. The structural concept of the church consists of five shells that are structurally independent. Each shell consists of three steel arches which are mutually connected by girders. At the top and the bottom side of each shell a membrane is positioned. Onto the lower membrane placeholders are welded in crucifix shape, which hold an insulation layer. At the inside of the church the stamp of the crucifix weld is slightly visible, effectively bringing a smooth appearance to the inner fabric. The lower membranes of the two main shells have a valley cable which creates a strong curvature in the lower fabric, resulting in a strong visual impact at the inside. The outer fabric of the two main shells also has a valley cable but it does not influence the shape of the fabric, leading to a normal saddle shape form. This creates a large space between the outer and inner fabric, giving room to the internal steel structure and even allowing for the use of straight girders instead of curved ones.

The outer and inner layers of fabric are mutually connected by a closing slab wrapped around the steel arches. Because this is a doubly curved membrane component, it is also treated as a membrane. To be able to formfind the fabric slab, a contact surface analysis is conducted. As the fabric continues all around the shells, it proved cumbersome to attach the façade, which is placed between the overlap of the different shells, to the supporting steel structure. This was solved by creating holes in the fabric at a certain distance from each other. This enabled a vertical placeholder to go trough the fabric to connect the secondary steel structure of the façade with the main bearing structure. The gap between the secondary steel structure and the fabric is closed by a slab that enables movement of the fabric.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Hybrid

-

Type (code)

Ferrari Fluotop T2 1202

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Mari Baauw, René Olivier (Royal Haskoning)

-

Engineers

Tentech BV

Royal Haskoning

-

Contractors

Buitink Zeilmakerij

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Evi Corne