Greenhouse project FLORA

General information

-

Location address

Cologne

-

Location country

Germany

-

Year of construction

2004

-

Name of the client/building owner

FLORA Cologne

- Function of building

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Primary function of the tensile structure

- Space defining elements

Description

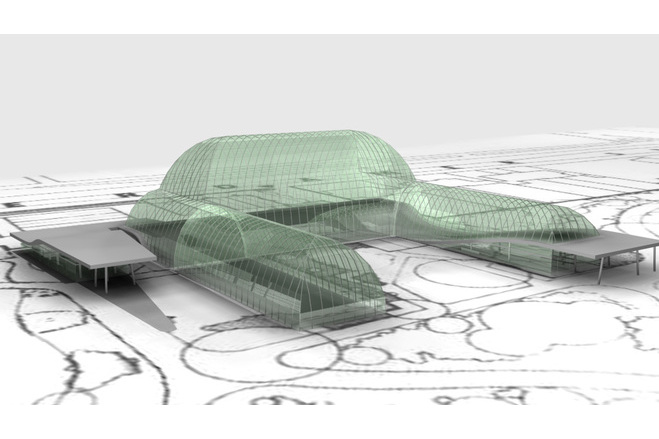

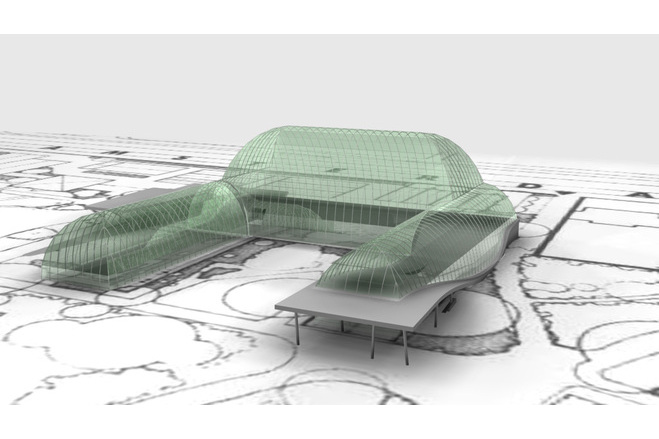

The architect's office Königs Architekten, Cologne was given the job of carrying out a design study to determine the possibilities of building a new greenhouse for the Cologne FLORA.

An important aspect thereby was to achieve an optimisation of the geometry and the materiality, which not only does justice to the architectural appearance, but also contributes to the optimisation of both functions and costs.

Greenhouse parameters

The following three parameters needed to be taken into consideration when planning the greenhouse:

1. Minimum of construction elements with greatest possible freedom from supports

2. Maximum UV utilization with greatest possible thermal insulation

3. Maximum corrosion protection of the load-bearing structure by permanent tropical humidity

1. Structural Analysis

The selected geometry follows the support line in the form of a parabolic curve. Thus the use of steel in the primary construction can be minimised - with the interior being completely free of supports. At the same time, the small steel cross sections (HEB 280 / IPE 220) with a crown height of up to 18m minimise the casting of shadows on the tropical plants.

The line of the curve permanently guarantees a vertical angle of light during the day, so that the reflection part of the light can be minimised and the UV exploitation can be optimised. This principle has already been used in classical greenhouse constructions (for example Kew Gardens, London).

2. Façade Analysis

Classical insulating glazing is unsuitable for greenhouses, since the degree of UV-transmission is too low. Single glazing on the other hand has proved to be unsatisfactory because the transmission losses of heat energy are too high.

A membrane construction out of ETFE film has shown itself to be a feasible alternative, since the UV-transmission of 91.7% - 95% is considerably higher than that of glass. At the same time the U-coefficient can be optimised with a multi-layer construction. Two-layer variations have a U-coefficient of 2.5 to 3.0 W/m2K, whereas three-layer constructions can achieve a U- coefficient of 1.8 to 2.0 W/m2K.

However, by pneumatic pre-stressing membrane constructions dominate in their pillow optics and would need to be integrated architecturally accordingly. At the same time, the susceptibility to the effects of hailstones must be taken into account.

Membrane Solutions

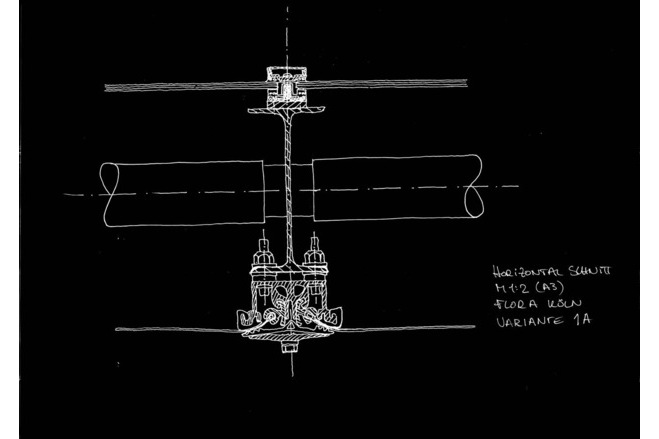

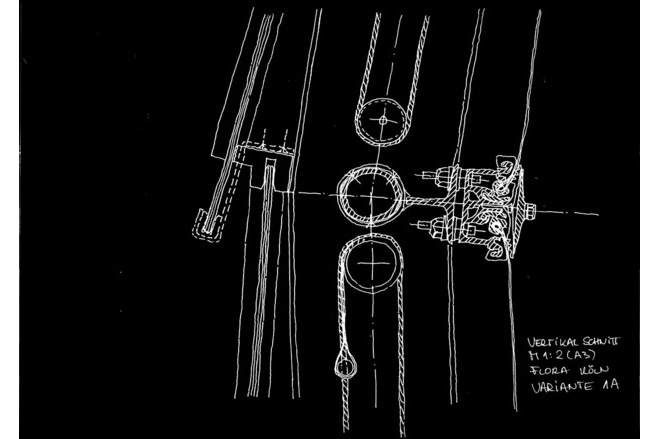

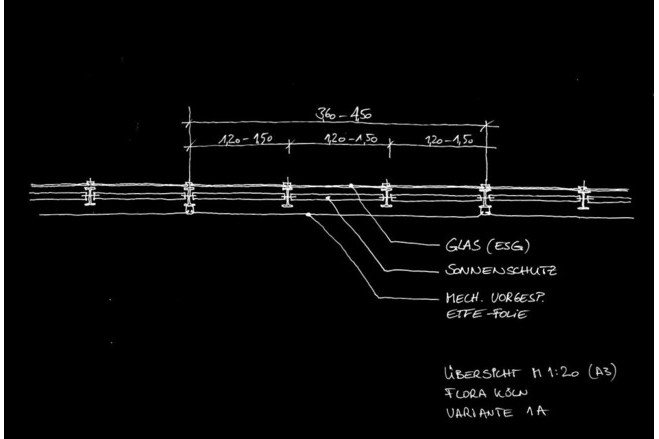

Taking into account the aspects mentioned above, we have developed a new alternative for the covering of the FLORA greenhouse together with Rudi Scheuermann, façade planner with ARUP, Berlin: a combination of a tempered glass cover on the outside with mechanically pre-stretched ETFE film on the inside.

The entire construction remains corrosion proof between the tempered glass and the ETFE film, which is an advantage by permanent tropical humidity values. At the same time, an extendable sun protector could be installed in the gap between the tempered glass and the ETFE film, which protects the plants against overheating.

The internal ETFE membrane can also fulfil the protective function against falling glass from the outside layer - a costly installation of laminated glass can thus be avoided.

In order to avoid condensation fallout in the construction gap, the gap should be rinsed permanently with dry air. The achievable U-coefficient would lie between 2.5 - 3.0 W/m2K.

The bend of the parabolic curves of the primary construction allows a simple mechanical pre-stretching of the internal membrane covering in the opposite direction. The external panes of tempered glass can be bent over a relatively large radius without any difficulty, so that they can follow the geometry precisely.

Result

Transparent ETFE membranes are particularly suitable for use in greenhouses. The weight reduction in comparison with conventional glazing leads to reduced steel tonnage; the casting of shadows and costs can be reduced.

Current technology allows precise fabrication as well as geometrically complicated contours. The UV-transmission and combinability in several layers makes ETFE film a superior material for this building task.

The new combination of ETFE film with tempered glass, which we have developed for the FLORA greenhouse in Cologne, demonstrates that the possible areas of use for membranes have not been exhausted by a long way and can be further optimised.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Foil

-

Material Fabric/Foil

ETFE-foil

Main dimensions and form

-

Covered surface (m2)

4000

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Koenigs Architekten

-

Engineers

Arup

Editor

-

Editor

Thomas Van der Velde