Festival Pavilion Trentino

General information

-

Home page

https://www.macotechnology.com/portfolio/festival-delleconomia-di-trento/

-

Location address

Trento

-

Location country

Italy

-

Year of construction

2016

-

Name of the client/building owner

Provincia Autonoma di Trento

-

Function of building

Exhibition

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Number of layers

double-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Daylight gains

- Rain protection

- Space defining elements

- Sun protection

- Wind protection

Description

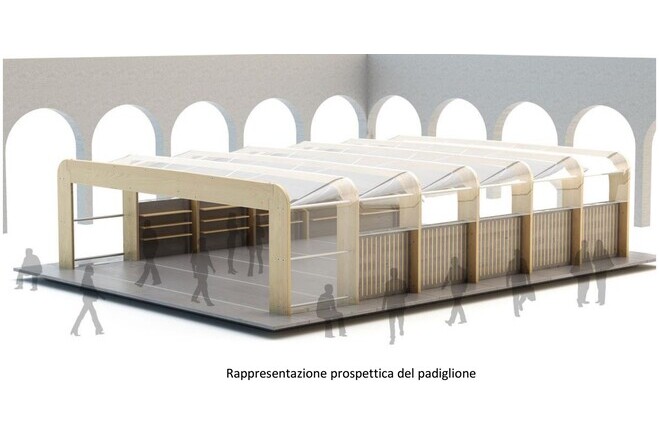

Design concept

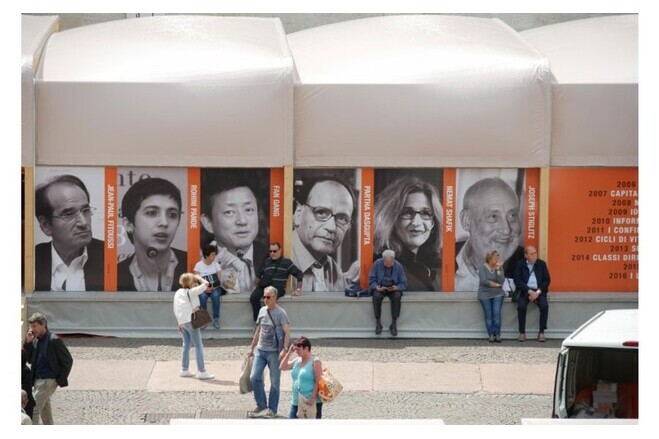

The design concept developed by Monica Armani is based on a construction system traditionally used for saw-tooth roofs and adapted to the temporary architecture in order to provide a practical way to create modular structures with accurate details obtained by means of a competent mix between technical innovations and building materials linked to the local traditions and to innovative manufacturing companies. The architect successfully designed a large design object which became a “special place” to be used to present people and stories to the public in the beautiful landscape of Trento and its province. Originally designed for the Trento Economics Festival 2016, the pavilion is currently used to host several other cultural events across the entire year.

The peculiar design is characterized by a set of timber portal frames linked to the local timber industry and by a saw-tooth roofs an inflated membrane cladding inspired by the alpenglow which paints the Dolomites with a reddish glow after sunset or before sunrise.

The pavilion is the last achievement of the project TEMPO, a collection of products, exposition stands and buildings designed by Studio Armani for temporary applications in order to address the contemporary trends in architecture characterized by rapid social changes with the consequent rapid evolution of the users’ requirements which hardly fit the traditional approaches in construction.

Load bearing structure

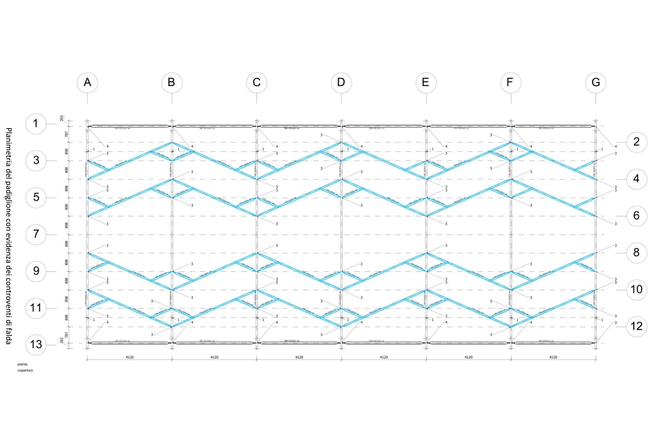

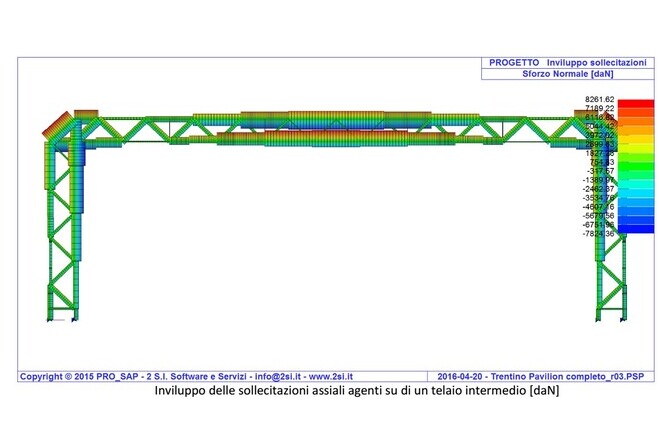

The structure has an overall cuboid shape which measures 11,84mx24,72m in plan with a maximum height of 4,16m. The seven loadbearing portals are arranged on an orthogonal grid and maintained at a prefixed distance (5.12m) by means of a set of purlins.

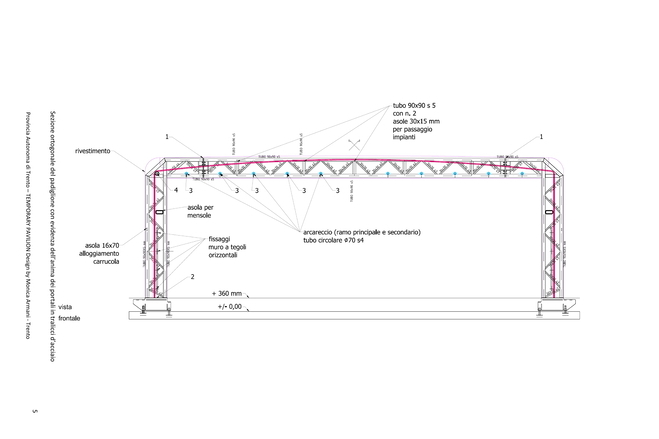

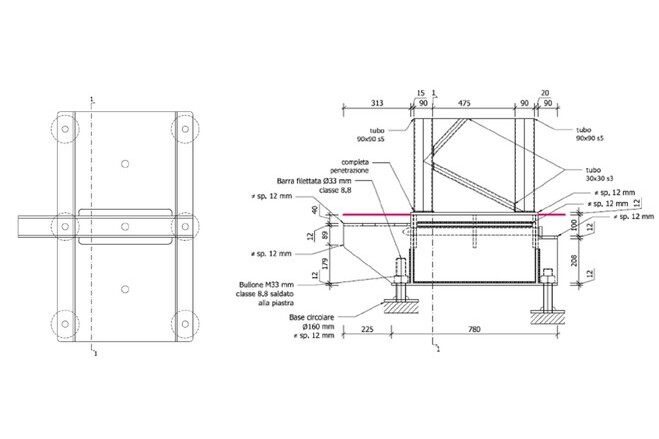

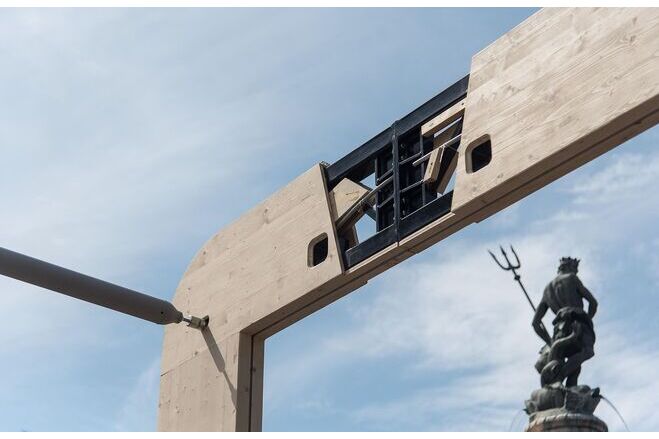

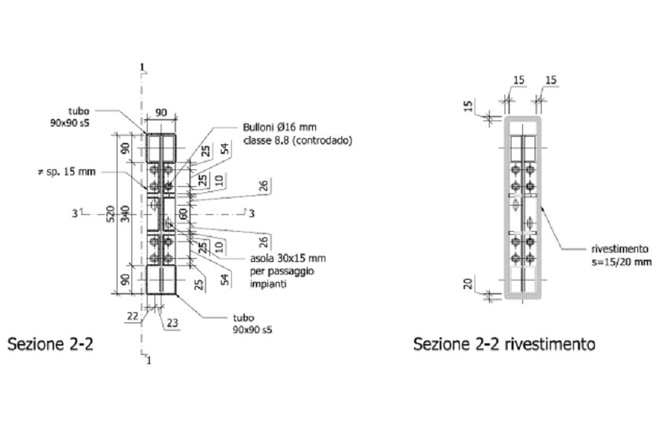

Each portal measures 11,84mx4,16m and it is made of a steel truss realized with steel (S275) square hollow sections welded together and reinforced with steel plates 10mm and 15mm thick. The top and bottom cords are obtained using a profile 90mmx90mm with a thickness of 5mm, the diagonals are made of a profile 30mmx30mm, 3mm thick. The portals are connected to the basement through pinned connections aligned with the orthogonal direction of the structural grid in order to help the installation of the portals which are assembled at ground level and then lifted from the horizontal to the vertical position. The steel trusses are cladded with a timber finish with a thickness variable between 15mm and 20mm.

There are 24 purlins in total, 4 between each pair of portal frames. Each purlin is obtained using steel hollow circular tubes (∅101,6mm, 5 and 6mm thick; ∅70mm, 4mm thick) and has a peculiar Y fork at each end designed to increase the lateral stability of the structure.

The lateral stability is also increased by a set of sandwich panels made of timber (20+54+20mm) bonded (polyurethane adhesive) with corrugated metal sheets (A55-P770-G6 HI-BOND 0,8mm thick) placed along the longitudinal lateral walls.

Inflated envelope

The envelope of the pavilion is based on a double layer inflated cushion. The external layer is made of a PVC coated polyester fabric Précontraint 502 Serge Ferrari®, the internal layer is made of Giovanardi VINITEX 9x9, a PVC foil reinforced with polyester yarns. The stability of the cushion is provided by the internal pressure (approx. 220Pa). The cushions are attached to the loadbearing structures through a structural flap along the high points and by means of an aluminium keder rail along the low points. The combination of the two materials creates a peculiar effect in the inner space of the pavilion. The almost transparent VINITEX membrane makes the volume more spacious and airier and provides a nice reflected light from the spotlights oriented towards the roof. The external coated fabric provides protection from the direct solar radiation during the day and creates an eye-catching effect for the visitors approaching the pavilion from the square. The colours have been carefully chosen to match the historic context and are inspired by the reddish glow of the alpenglow.

Transportation and installation

The pavilion has been designed to be fully manufactured off site and transported in small components designed to fit the standard sizes of the trucking industry. Each portal is made of 5 components, two pinned joints for the connection to the basement, 2 vertical truss columns and one truss beam connected each other with bespoke joints. Each beam is assembled at ground level and lifted thanks to the movement allowed by the pinned joint. The first portal is connected to the second portal with the purlins becoming a rigid support for the additional modules. Once the structure is complete, the inflated envelope is installed, the cushion connected to the circuit for the pressurized air and inflated by means of a dedicated blower. The pavilion is then completed by adding the basement which includes a rigid structure, the ballasts, the adjustable supports of the timber deck and the final top finish.

Conclusion

This project is an example of how membrane structures are a potential answer to challenging requirements which include a distinctive architectural appeal, reduced installation time and costs, optimized weight of the components, reduced packaging volumes and limited environmental impact of the structure.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

Ferrari, Precontraint 502

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

280

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Mobile

Involved companies

-

Architects

Monica Armani

-

Engineers

Maco Technology srl

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Marijke M. Mollaert